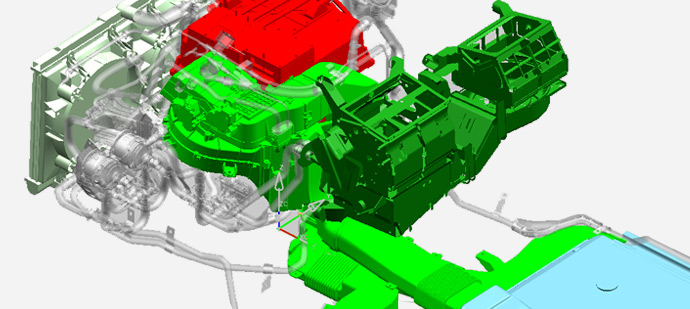

The skills of computational fluid dynamics cfd experts traditionally have been necessary for electric powertrain as well as component level design and to expose underlying limiting phenomena.

Cfd for electric car battery cooling system design.

However relying solely on cfd experts today can result in either slower deployment or under achievement of the expected design.

Experimental results reveal a promising cooling effect with a reasonable amount of power dissipation.

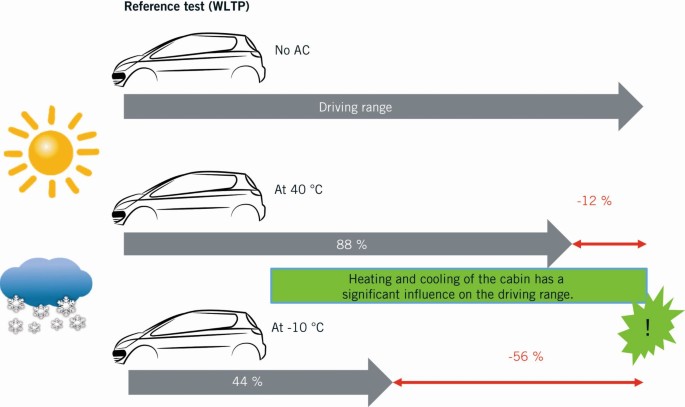

Cooling strategies air cooling.

Cfd analysis was performed using the fluent software to design the thermal system for a hybrid vehicle battery pack.

Moreover the experimental test shows that the battery surface temperature drops around 43 ºc from 55 ºc to 12 ºc using tec based water cooling system for.

Acusolve used for cfd modelling in research projects 4.

Objective functions of mean temperature pressure drop and temperature uniformity.

Detailed experiments are carried out on a simulated electric vehicle battery system.

The battery packs are located on top of a cold plate which consists of cooling channels to direct the cooling liquid flow below the battery packs.

This demo shows an electric vehicle ev battery cooling system.

Star ccm solver and battery simulation module bms application to predict the temperature distribution within a module.

And analyzed for mild hybrid vehicle application.

Cooled battery thermal management system design has been proposed.

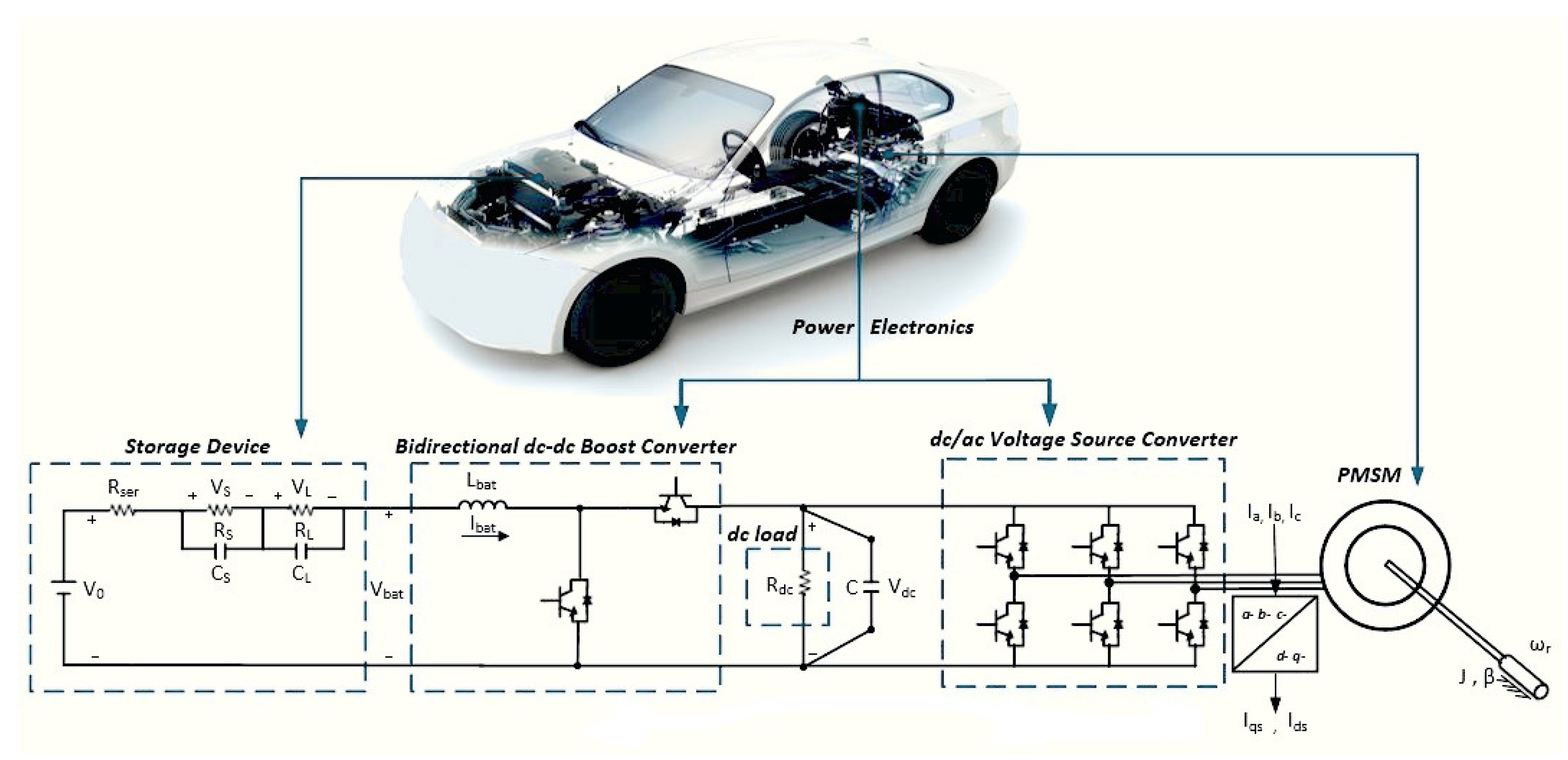

A 1d cfd simulation also called system level cfd is a type of cfd simulation that focuses on the entire system rather than on the details of a specific component.

2582 5208 international research journal of modernization in engineering technology and science.

Design and thermal analysis of cylindrical shaped lithium ion electric car battery system by varying cooling methods using cfd software.

Mean temperature and pressure drop optimum designs have wide coolant channels.

One of the important design considerations is how to model the battery cooling pack.

Battery cooling packs modeled in 1d cfd.

Temperature uniformity optimum design has channels of variable width.

The lg chem lithium ion batteries have an aluminum plate that we will uti.

For battery cooling system design across mild hybrids mhev plug in hybrids phev and battery electric vehicles bev.

The heat absorbed by the cooling liquid is transported to the heating cooling unit.

Numerical optimization was applied to improve its design.

System thermal modelling 3.

Electrical vehicle battery pack cooling strategies 2.